The manufacturing sector is undergoing a seismic shift, driven by the relentless pursuit of efficiency, precision, and flexibility. At the heart of this transformation lies Intelligent Manufacturing – a paradigm leveraging technologies like Artificial Intelligence (AI), Machine Learning (ML), and the Industrial Internet of Things (IIoT) to optimize production processes. Among the critical components enabling this intelligent revolution are CNC (Computer Numerical Control) machine tools. And underpinning the functionality of these sophisticated machines are gear motors – often unseen but undeniably vital. This article explores the crucial role gear motor manufacturers, specifically companies like MES-Drive, play in the advancement of intelligent CNC manufacturing, looking at current trends, challenges, and future opportunities.

Traditional CNC machining relied heavily on human input and manual adjustments. Modern intelligent CNC systems, however, are becoming increasingly autonomous, capable of adapting to changing requirements, predicting potential issues, and optimizing performance in real-time. This intelligence is achieved through a confluence of technologies. AI algorithms analyze sensor data from the machine tool (vibration, temperature, tool wear) to predict failures before they occur, minimizing downtime. ML models optimize cutting parameters based on material properties and desired part specifications, leading to improved surface finishes and reduced cycle times. IIoT connectivity enables remote monitoring, diagnostics, and predictive maintenance, creating a truly connected manufacturing ecosystem.

The benefits of this intelligent approach are substantial. Manufacturers experience increased productivity, reduced scrap rates, lower energy consumption, and enhanced product quality. Furthermore, intelligent CNC systems allow for greater flexibility, enabling rapid prototyping and custom manufacturing on demand – a critical advantage in today's dynamic market. The pandemic further accelerated this trend as companies sought ways to minimize reliance on extended supply chains and maintain production agility.

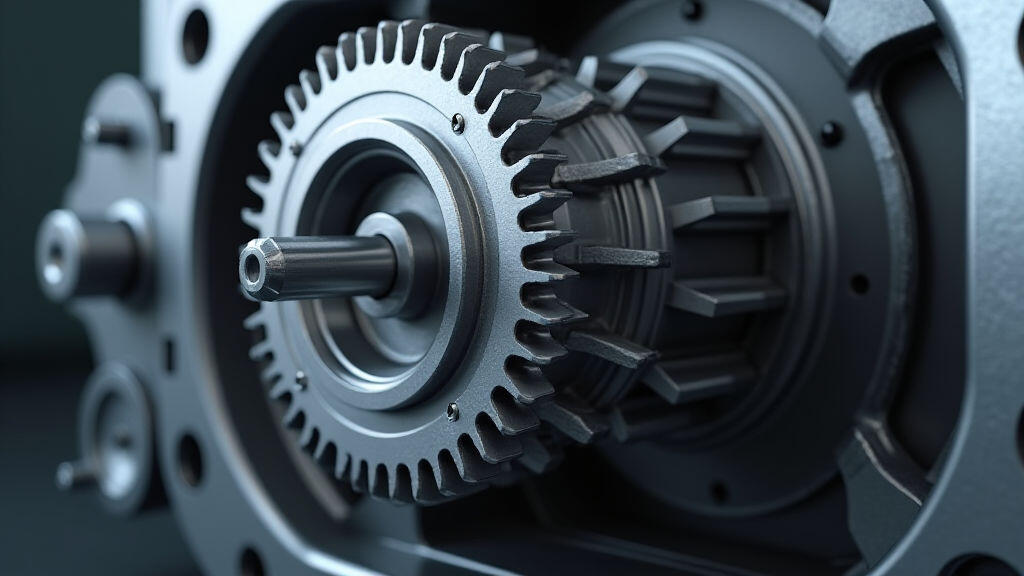

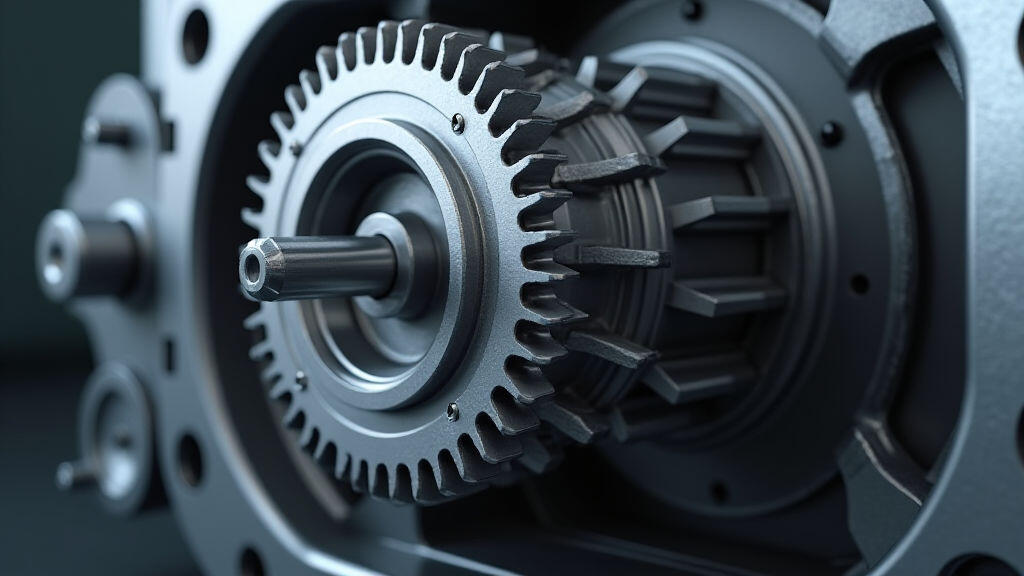

CNC machine tools rely on precise and controlled movement across multiple axes. Gear motors provide this precise motion by converting rotational motion from an electric motor into a lower, higher-torque output with significantly reduced speed. This power transmission is essential for driving spindles, linear guides, and other critical components within CNC machines.

Different types of gear motors are employed in CNC applications, depending on the specific requirements. Planetary gear motors offer high torque density and compact size, ideal for space-constrained environments. Harmonic drive gear motors provide extremely high reduction ratios and precise positioning, making them suitable for high-accuracy applications. Worm gear motors are known for their self-locking capabilities, providing reliable holding torque when the motor is stopped.

The quality and performance of the gear motor directly impact the overall efficiency, accuracy, and reliability of the CNC machine. A poorly designed or manufactured gear motor can lead to vibrations, noise, and premature wear, ultimately compromising the entire machining process.

Companies like MES-Drive are at the forefront of gear motor innovation, continuously developing and refining products to meet the evolving demands of intelligent CNC manufacturing. MES-Drive's strengths lie in several key areas:

Furthermore, MES-Drive is heavily invested in exploring new materials and manufacturing processes, including additive manufacturing, to further enhance the performance and capabilities of its gear motors.

While the future of intelligent CNC manufacturing is bright, several challenges remain. The increasing complexity of CNC systems requires gear motors with ever-higher levels of precision and reliability. The integration of IIoT capabilities requires robust cybersecurity measures to protect against data breaches and malicious attacks. And the rising cost of raw materials presents a challenge to maintaining competitive pricing.

However, these challenges also present opportunities for innovation. The development of new materials and manufacturing processes can lead to more efficient and cost-effective gear motors. Advanced AI algorithms can be used to optimize gear motor designs for specific applications. And the increasing demand for automation and precision machining is driving growth in the gear motor market.

The convergence of advanced manufacturing technologies and intelligent CNC systems is creating a powerful synergy. Gear motor manufacturers like MES-Drive are poised to play a central role in this revolution. We can expect to see:

In conclusion, gear motor manufacturers are not simply suppliers of components; they are integral partners in the intelligent manufacturing revolution. By continuously innovating and adapting to the evolving needs of CNC machine tool manufacturers, companies like MES-Drive are driving progress towards a more efficient, precise, and sustainable future for the manufacturing industry. As the global manufacturing landscape continues to evolve in response to events like the ongoing semiconductor shortage, and the push for reshoring, the demand for high-performance, reliable gear motors will only intensify, solidifying their core role in achieving manufacturing excellence.

Leave A Reply

Your email address will not be published. Required fiels are marked